- Prev:None

- Next:None

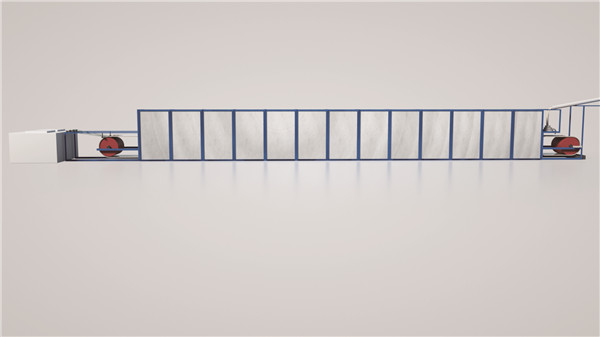

General summary of high crystal gypsum ceiling production equipment | |||

Serial number | name | details | remarks |

1 | Total power of equipment | 40KW | |

2 | Overall dimensions of equipment | 70×1.6×2.1(m) | Length, width and height |

3 | Die size | Outer diameter 680 × 680 × 20 (mm) | The pattern and inner diameter of the mould are customized according to customer requirements |

4 | Number of molds | 200 tablets | |

5 | Equipment output | 500-700 tablets | Production per hour |

6 | Amount of labor | 4-5 persons | |

7 | Site requirements | 80×4(m) | Length and width |

8 | Storage bin capacity | 60m³×2 | |

9 | Storage yard | 200 ㎡ | |

10 | Size of drying board rack | 6×1×(2.1-1.9)(m) | Length and width |

11 | Composition of drying board frame (optional) | Angle iron, asbestos tile, steel column, rubber pad, steel column rubber sleeve | 4 ා thick wall angle iron - 11 pieces, asbestos tile - 9 pieces; rubber pad - 48m, steel column - 504 pieces, steel column rubber sleeve - 504 pieces# |

12 | Quantity of drying board rack required (optional) | 200 个 | The number of drying racks required for one drying cycle of one equipment |

13 | Required field for drying board (optional) | 4500 ㎡ | Site required for one drying cycle of one equipment |

14 | Drying cycle | 15-20 days | |

High crystal gypsum ceiling production equipment process and processing equipment:

mixed ingredients

Proportioning: gypsum powder + additive + glass fiber wire application equipment: batching machine function: is to match all raw materials in the production process

pulping

Equipment used: pulping machine, slurry storage tank, mixer role: will match the good ingredients for processing, mixing processing methods are manual and mechanical methods

Plate making

The use of equipment: plate making machine role: is the use of tools for product compression molding

Demoulding

Use of equipment: demoulding machine role: plate making good products separated from the mold. There are three ways to stack a series of products: 1. Manual stacking. Lighter objects. 2. Forklift stacking. It is commonly used in the warehouse. 3. Crane palletizing. Production lines, heavy objects are commonly used.

High crystal gypsum board ceiling production equipment advantages and functions: 1. High degree of automation, equipment operation is simple, only need to carry out correct operation training can work, save labor, reduce labor costs, improve work efficiency. 2. There are no restrictions on the production site. As long as the production site is safe, the facilities are complete, and there is water and electricity, it can work. 3. Customized processing, which can be customized according to the needs of customers, only need to provide the size of the product. Ensure the quality of products, avoid waste, and make the treatment effect better. 4. The composition of raw materials is simple and there is no regional limitation.

High crystal gypsum ceiling production equipment application scope: commercial buildings: business buildings, entertainment places, shopping malls, hotels, industrial buildings: factories, warehouses, residential buildings: new residential, renovation Public places: hospitals, theaters and stations are mainly used for industrial boards such as wall, ceiling, floor, furniture, road sound insulation, sound absorption barrier, ship compartment and air duct, as well as sound absorption wall, sound-absorbing ceiling, cast-in-place wall, composite wall panel and other fields. The materials are light, high-strength, heat-insulating, fireproof and moisture-proof.