- Prev:None

- Next:PVC gypsum board double faced veneering machine

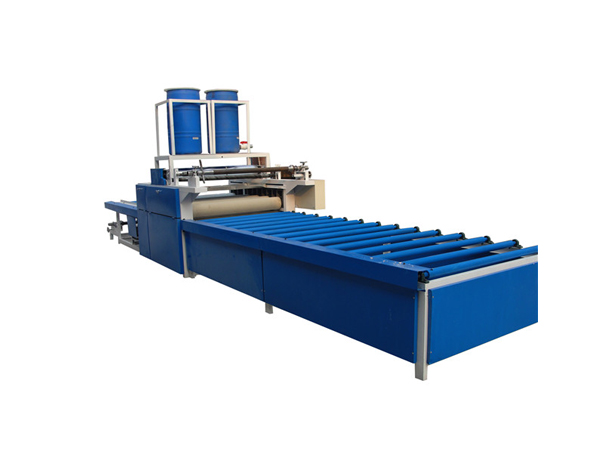

PVC gypsum board veneering machine production line | ||||||

Veneering machine (including automatic board loading and unloading machine) | Equipment name | Cutting machine (including automatic board loading machine and dust remover) | Equipment name | Edging machine | Equipment name | packer |

PLC control | Electrical control mode | PLC control | Electrical control mode | PLC control | Electrical control mode | PLC control |

13 | Total power (kw) | 20 | Total power (kw) | 6 | Total power (kw) | 30 |

14.5 * 3.7 * (2.1 above ground; 1.3 underground) | Size (m) Length * width * height | 14.5 * 3.4 * (dust remover 3.3; cutter 1.5 above ground, 0.8 underground) | Size (m) Length * width * height | Equipment size 10.5 * 1.25 * 1.1 Floor space 5.5 * 5.7 * 1.1 | Size (m) Length * width * height | 15.2*1.76*1.25 |

10.1 | Total weight (T) | 6.3 | Total weight (T) | 1.3 | Total weight (T) | 2.7 |

3000 | Maximum processing length (mm) | 3000 | Maximum processing length (mm) | 620 | Maximum processing length (mm) | 1220 |

1300 | Maximum processing width (mm) | 1300 | Maximum processing width (mm) | 620 | Maximum processing width (mm) | 650 |

12.5 | Maximum machining thickness (mm) | 12.5 | Maximum machining thickness (mm) | 12.5 | Maximum machining thickness (mm) | 100 |

660 | Maximum production capacity (PCS / HR) | 500 | Maximum production capacity (PCS / HR) | 1440 | Maximum production capacity (bag / HR) | Small board 700,Big board 260 |

Three to four people | Operator required | 3 | Operator required | 2 | Operator required | Small board 4, Big board 6 |

Normal working temperature - 2 ℃ - 40 ℃ If the temperature is too low, it is necessary to heat the rubber bucket with heating coil | remarks | remarks | remarks | heating temperature Small plate: 230 ℃ Large plate: 280 ℃ | ||